Filobel Yarn Processing

Filobel is attentive in every step to the processing phase of the product through highly certified procedures and according to European regulations.

In particular, the processing includes phases of gassing, reeling, hanks to cone winding and rewinding.

Stages Of Processing

Description

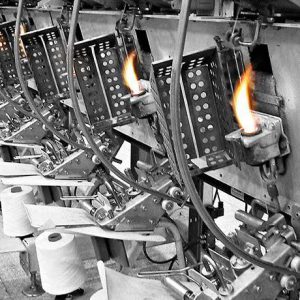

Gassing is carried out mainly on cotton yarns in order to eliminate the effect of surface hairiness, due to the presence of fibers partially protruding from the body of the yarn. It is carried out before the final winding, on raw yarns. In the case of cotton, gassing is carried out on the yarns intended for mercerization, as the elimination of surface hairiness increases the degree of brightness of the yarn after dyeing. Gassing consists in a passage of the yarn through a flame, at such a speed that the protruding fibers are burnt and the fibers that make up the yarn are not modified.

Description

Description Operation performed with the reeling machine, winding a textile fiber yarn in hanks before the mercerizing dyeing phase.

Description

The dried hanks are wound on a cone and during this operation are coated with paraffin.

Description

This is a simple but crucial step. The thread is put from the dye cones to the paper cones. We guarantee that the density will not change between the cones and within the cone itself, as it could generate different tensions in the knitting machine and defects. During this step, the wire is coated with a layer of paraffin to reduce friction and have a smooth release during final use.

Description

The first phase of doubling consists in coupling two or more yarns and then moving on to the twisting phase, an operation which consists in twisting together two or more yarns already individually twisted, in order to obtain thicker and more resistant yarns.

Description

The dyeing bobbins are fed into pressurized machines with pumps powerful enough to evenly penetrate the yarn. First they are purged to remove oils, impurities and spinning dirt. They are then dyed and finished with special softeners based on the yarn and shade to give the cotton a smooth and silky touch.

Description

In technical language, this name refers to an operation which significantly increases the value of the cotton fiber by means of a treatment with concentrated solutions of caustic soda. Mercerization gives the fiber in particular a brilliant appearance, a permanent luster, similar to that of silk, a higher specific weight, greater tensile strength, greater elasticity and finally greater affinity for almost all natural coloring substances or synthetic. But above all, mercerization determines, with the action of the alkali, the shortening of the fiber. It is through this shortening and the consequent mechanical stretching operation to give the fiber its original length that the deep apparent structural modifications of the fiber take place.